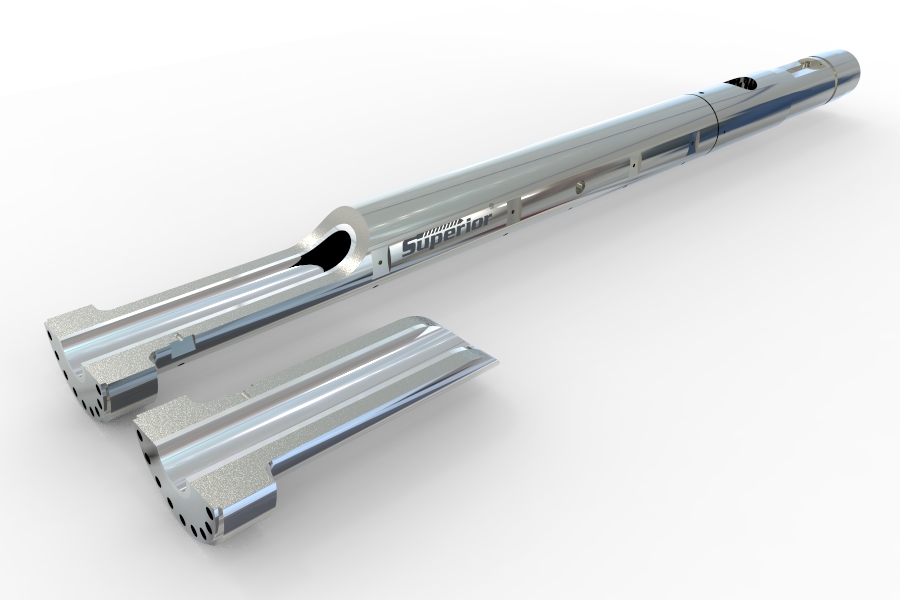

SBK3 series are bimetallic barrels processed with high temperature centrifugal casting.

The base material is made of 40Cr, 42CrMo and the Iron-based alloy powder selected from Stellite (Shanghai) Co., Ltd.

Characteristics:

Superior wear resistance, moderate corrosion resistance and high temperature resistance under 400°C

Hardness:

More than HRC 62°

Straight length: < 0.06/m

Diameter of production inner hole:φ 14- φ 250

Length of production part: 5000mm

Production range:

SBK3 is suitable for injecting moderate corrosion materials with less than 40% glass fiber content.