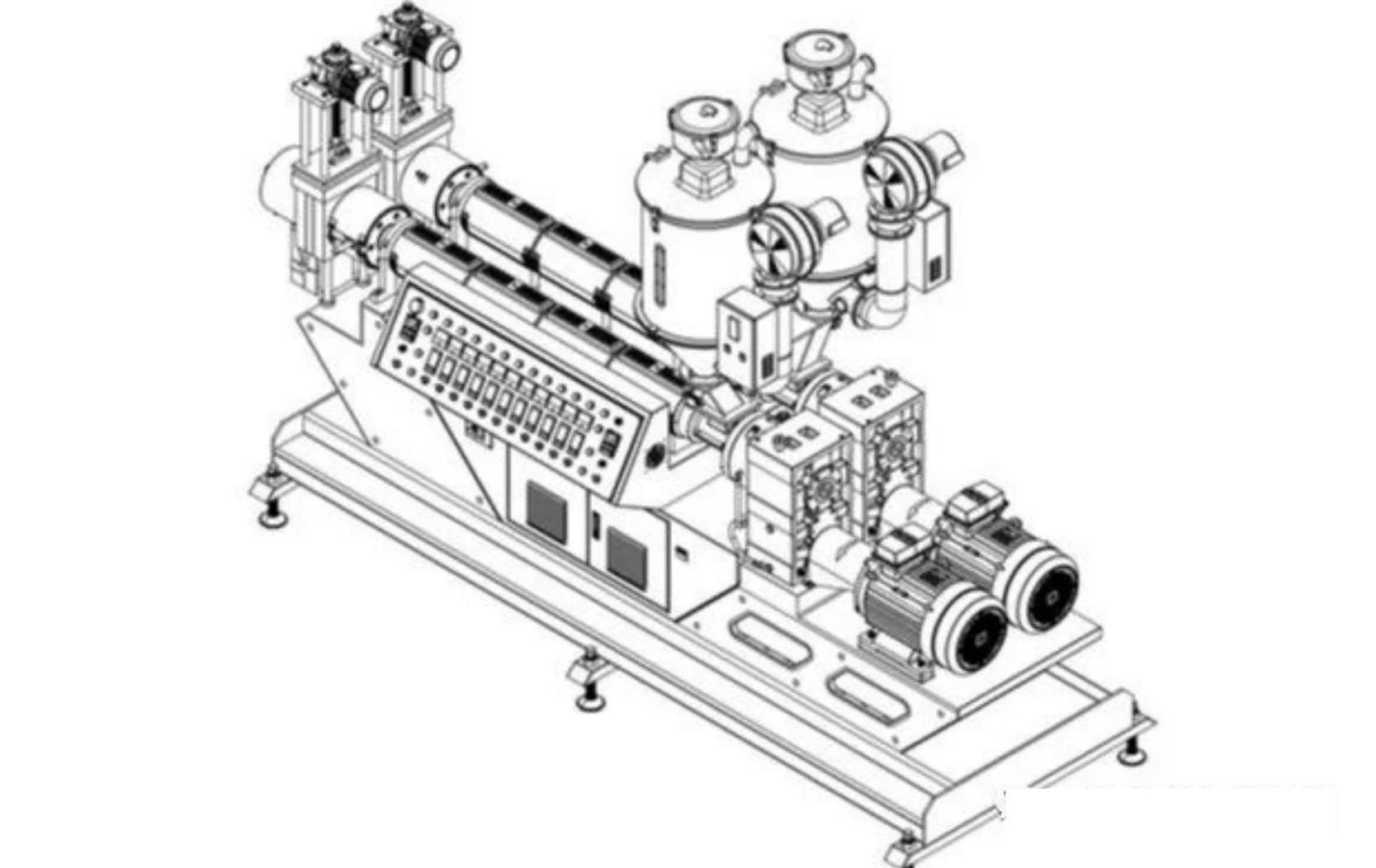

With the improvement of the production and processing technology of twin-screw extruders, they not only need to perform tasks such as feeding and plasticizing, but also have some requirements for dehydration, drying, etc. In order to better meet the different needs of users, twin-screw extruders must continuously improve their work efficiency and find ways to improve the quality of the manufactured products. So, how should we do it?

Here are specific methods to improve production efficiency and product quality!

- How to improve work efficiency of twin-screw extruder:

Improving work efficiency is one of the crucial goals in the development, design, and research of new co rotating twin-screw extruders. It can also be achieved by increasing screw speed, improving plasticization and mixing levels, and other methods. Expanding the depth of the screw groove can significantly increase the conveying capacity at the same screw speed. On the other hand, the plasticization and mixing level of the screw must also be increased, which requires the screw to be able to withstand higher torque.

At high screw speeds, the residence time of the material in the extruder decreases, which may result in insufficient plasticization, melting, and mixing of the material.

Therefore, it is necessary to appropriately increase the length of the screw, which will inevitably result in the twin-screw extruder actually carrying an increase in torque and power.

Expanding the free volume of the screw groove is also a crucial factor. It is necessary for threaded components to have a large free volume in the feeding and stripping sections. For high-density materials, expanding the free volume of the feeding section and the filling degree of the material in the screw groove can greatly improve the processing capacity of the extruder.

Improving torque and speed requires careful design of the reduction gearbox. To significantly improve the torque index of equipment, higher requirements will inevitably be put forward for the design and manufacturing level of transmission boxes.

The higher the torque, the higher the design, manufacturing accuracy, material strength, and heat treatment of parts such as gears, output shafts, and bearings in the transmission box. At the same time, the design, manufacturing accuracy of parts such as the core shaft, threaded components, and pinch plates of the screw must also be higher.

Because the free volume of the threaded component needs to be expanded, the center distance between the two screws will decrease while keeping the outer diameter of the screw constant. This will inevitably make the problem of limited installation space for the proportioning gear and thrust bearing more prominent.

- How to improve product quality of twin-screw extruder:

To achieve high product quality, the design of the plasticizing system, the core component of the extruder, is closely related.

The plasticizing system mainly includes screws and barrels. To meet various types of production and processing requirements, screws and barrels are generally designed as a modular combination structure. According to the function of each section, the screw can be divided into feeding section, plasticizing section, mixing section, exhaust section, and extrusion section. These sections have different roles in the extrusion process, their structures are not exactly the same, and the corresponding geometric parameters of the screw components are also different. Therefore, how to determine the geometric parameters of the threaded components becomes the key to the design of the plasticizing system.

For co rotating twin-screw, there is a certain correlation between the pitch to diameter ratio (i.e. the ratio of the center distance between the two screws to the screw radius), the number of thread heads, and the thread apex angle, which cannot be arbitrarily designed, otherwise there will be interference between the two screws.

To address this issue, the author obtained the theoretical end face curves of the two screws based on their motion trajectories. Using the three-dimensional solid modeling function of large-scale computer-aided design (CAD) software, a geometric modeling program for twin-screw was developed to display the three-dimensional solid graphics of the twin-screw. The geometric parameters of various types and specifications of self-cleaning threaded components were obtained, and the meshing of the two screws was verified.

In addition, project practice was also integrated, and with the help of computers, a three-dimensional solid modeling of double screws with gaps was completed. This can be used to check whether the gaps between the two screws are uniform, so that the material has no dead corners during the screw movement, ensuring that the screw has strong self-cleaning ability and can efficiently prevent material degradation due to prolonged residence in the machine. This undoubtedly provides a good production and processing method for producing high-end and high-quality plastic products.