SST700 screw is a vacuum sintered nickel-based alloy coated screw, suitable for high wear materials.

The base material is high quality alloy steel and the coating is imported ni-based self-fluxing alloy powder.

Characteristics:

excellent wear resistance, excellent corrosion resistance, metallurgical combination of

alloy layer and matrix. SST700 series match with SBK5 barrel

Suitable for injection molding:

all kinds of colored materials with high wear and corrosion.

Application:

Laser accessories, optical fiber, communication, motor, thermoset injection molding

Chemical composition of SST700 and SBK5:

| Composition(Typical) | % |

| Boron | 3.6 |

| Carbon | 0.55 |

| Chromium | 16.5 |

| Copper | 2.1 |

| Iron | 3.0 |

| Molybdenum | 3.5 |

| Nickel | Rem. |

| Silicon | 4.8 |

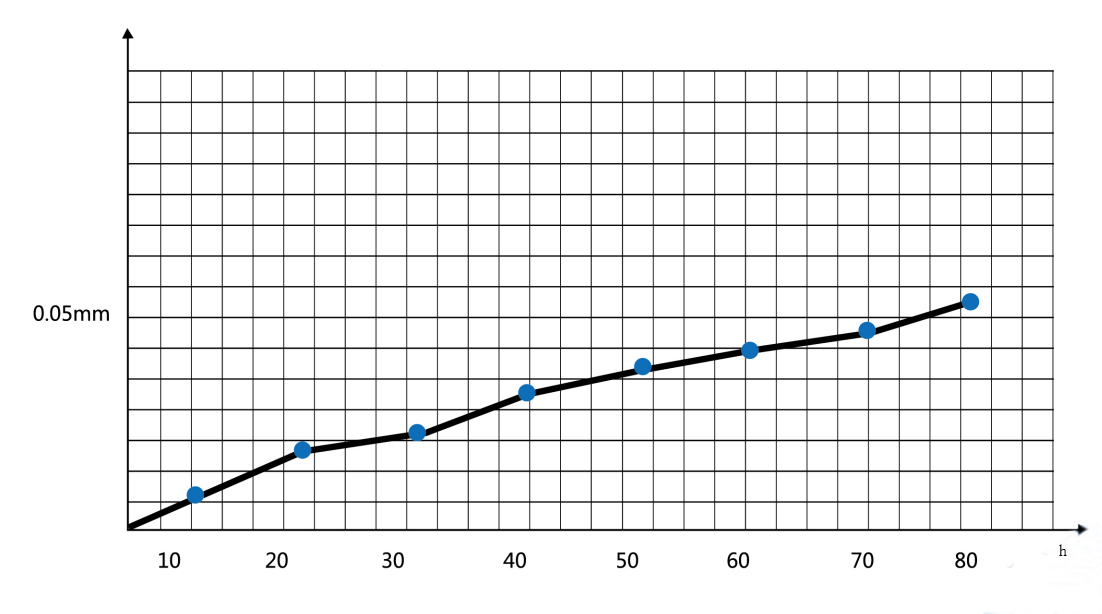

Parameter of wear test

Load 250CN, revolution 205.6 rpm, pure sliding dry friction, weighing the wear loss per 10 hours (g); the sealing and grinding sample is the upper sample Cr12MoV quenching, tempering, HRC:60. 1,59.9, 59.6 (fixed sample at 60°C)